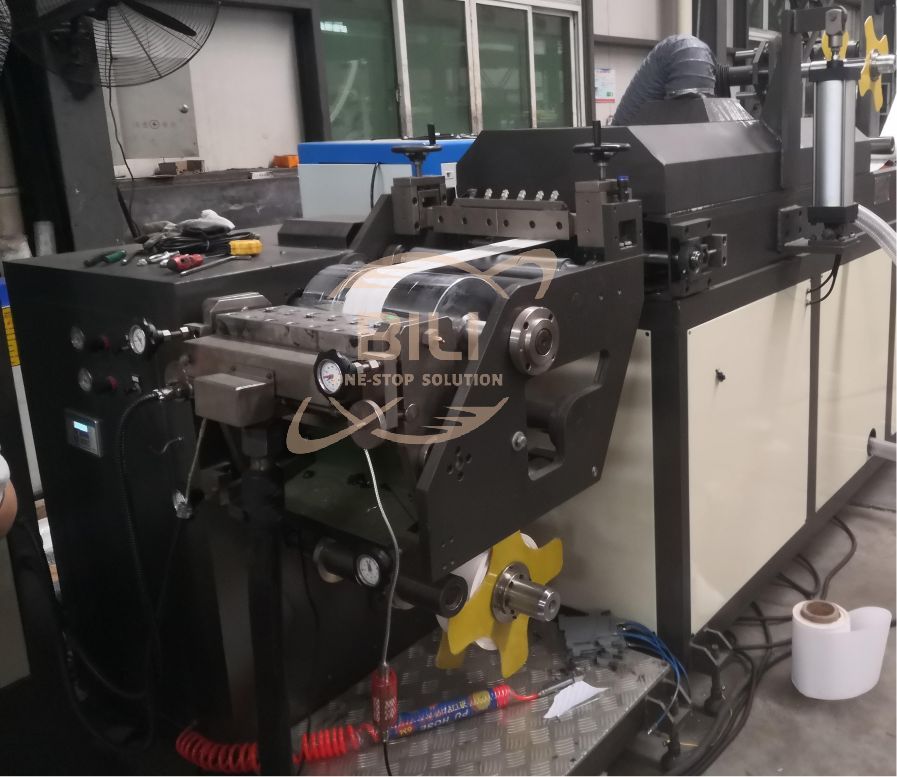

Some questions for butyl rubber tape coating machine

From what I understand, the drawing looks really good. It looks like it has an air cooling chamber directly following the extrusion area.This is a really nice touch and not something I had available on the Edge line. Beyond that, the conveyor system is pretty straight forward. Most of the trouble comes at the very start and end of the line.

Yes, it is for cooling the butyl after coating,

Start

Verify that the extruder is a mixtruder. If so, all you’ll need to do is mix in my compounds and curatives for fifteen minutes, and then commence with extrusion. I highly recommend this approach. If you mix in one machine and then extrude out of another, you’re going to have a lot of time and labor invested in moving material between machines. Since you are buying the compound pre-mixed from me, you want to be as streamlined as possible here and keep the amount of machinery needed to a minimum.

Our machine has no mixing function, and also can not change this extruder to mixextruder.

you need buy a mixer before our machine and try to mixer output butyl directly to extruder.

The overhead unwinder (I believe it’s the second unwinder in the drawing) needs to be mobile. The uncured flashing will be nipped in from this device. We have no way of knowing if the flashing will adhere well to the tape once it has been cooled off. It’s quite possible the flashing will need to nip in with the tape before going into the cooling chamber.

I do not know what’s the flashing? Is it butyl rubber that from extruder?

I think the flashing is butyl rubber , do not worry, it is no need, the cooling air capacity we can adjust, and it is have no very good cooling effect, because it is only cool by air, can be adhere very well, no need movable unwinder.

It looks like the slitting is to be done at the start of the line. Make sure the knife system is score slitting. They should be round blades, 2-3” in diameter. The beauty of score slitting is that you can perforate. Keeping the web intact throughout the extrusion process is so much easier than dealing with individually cut strands of tape. At the end of the line, where the operator unloads the rolls, he can simply cut through the perforations with a metal spatula.

I think the score slitting is do cut (like this- - - - - - - -), yes, after slit, it is perforate, and yes, at the end the operator can unload the roll and separate the roll easily.

End

I recommend an indexing winder, which this does not appear to be. With an indexing winder, you only need to use one spindle at a time. The other one is pre-cored. When the proper length is reached, the spindles exchange positions, allowing the operator to cut free Roll A, while using the same continuous web to start Roll B.

Automatic counter is a must. I’m pretty

I not understand very well, but our machine has two rewinder, one rewinder finish on roll, it can automatic change to another rewinder, each rewinder has one air shaft, Air expansion shaft has a key automatic gas expansion and automatic exhaust function

Contact: Mr. Laker Ruan

Phone: +86 13958847720

E-mail: hz.505050@163.com

Whatsapp:008613958847720

Add: 1088 Jingye Road, Hongluo Industry Zone, Ruian City , Zhejiang province, China

We chat